CNC Pipe Bending Machine Manufacturers, Suppliers and Traders in Chakan

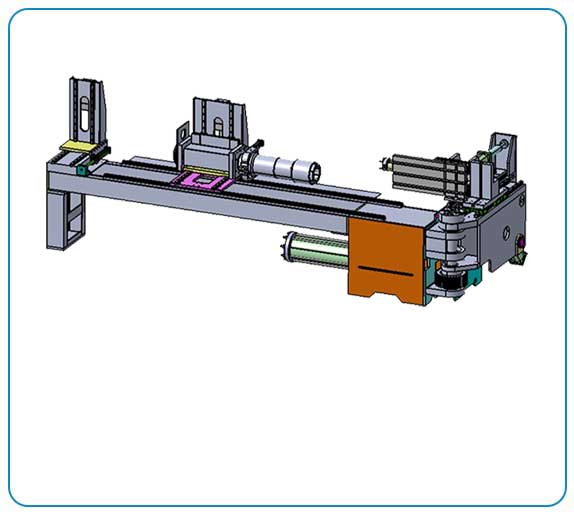

CNC Pipe Bending Machine Manufacturers in Chakan by Shree Tube Tech Engineering. We manufacture precision-engineered pipe bending machines of high quality and to let you know about ourselves we prolong back through experience that would count up to several years, which is a seasoned journey through the industry, going ahead with the technocrats to deliver futuristic CNC pipe bending machines Suppliers in Chakan to a diversified clientele that would range from automotive, construction, and heavy engineering fields.

For CNC Pipe Bending Machine in Chakan, advanced technology for the most advanced machines is what we have to offer. As a trusted CNC Pipe Bending Machine Traders in Chakan, we manufacture and supplier of this machine but mostly run it on a supply chain and then offer after-sale services. The user is provided with easy interface construction along with robust constructions to generate reliability in the results, as well as long durability which makes them last longer.

CNC Pipe Bending Machine Manufacturers in Chakan

Shree Tube Tech Engineering is known as the popular CNC Pipe Bending Machine Manufacturers in Chakan. Our company assures cutting-edge and viable solutions for fulfilling your pipe bending requirement. We provide CNC Pipe Bending Machine in Chakan, which are specially designed to deliver exceptional accuracy, high-speed performances, and versatility to various industries-from automotive to construction and aerospace.

Our wide range of suitable machines can bring several pipe sizes and materials to handle easily, as we are trusted CNC Pipe Bending Machine Suppliers in Chakan. Our machines are advanced with CNC technology, designed in such a way that every bend will be precise and that it will be consistent, avoiding errors, and adding to productivity. Being the leading CNC Pipe Bending Machine Traders in Chakan, we also facilitate our customers' best experience from installation to maintenance of their machines. Shree Tube Tech Engineering is the In-house Treatment Division wizard for you on having very high-quality CNC pipe bending Solutions according to the specifications. Choose us for reliability, performance, and outstanding value.

Types of CNC Pipe Bending Machine

Below some of the types of CNC Pipe Bending Machines are:

| Type of CNC Pipe Bending Machine | Description |

|---|---|

| CNC Hydraulic Pipe Bending Machine | Uses hydraulic power for bending large and thick pipes with high precision. |

| CNC Electric Pipe Bending Machine | Energizing and precise bending of smaller diameter pipes. |

| CNC Multi-stack Pipe Bending Machine | Bending several pipes at once improves production efficiency. |

| CNC Mandrel Pipe Bending Machine | Bending is accompanied by a mandrel for smooth bends and avoiding deformation. |

| CNC Rotary Draw Pipe Bending Machine | Maintains accurate, smooth bends for complex curvatures while minimizing distortion. |

Specifications of CNC Pipe Bending Machine

A few details of the CNC Pipe Bending Machine are as follows:

| Feature | Details |

|---|---|

| Machine Type | CNC Hydraulic, CNC Electric, CNC Mandrel, CNC Rotary Draw, CNC Multi-stack |

| Bending Capacity | 6 mm to 200 mm pipe diameter |

| Bending Radius | 1.5 x pipe diameter to 6 x pipe diameter |

| Pipe Material Compatibility | Carbon steel, stainless steel, aluminum, copper, brass, and other alloys |

| Bending Accuracy | ±0.1 mm |

| Maximum Bending Angle | 180° or custom |

| Control System | Siemens, Mitsubishi, or custom PLC and CNC control with touchscreen interface |

| Automation Features | Fully automated CNC control for programmable angles, radii, and multiple bends |

| Power Supply | Hydraulic: 220V to 440V AC; Electric: 380V AC or customized for specific needs |

| Max Pipe Length | Up to 6 meters |

| Speed | Up to 20 meters per minute |

Benefits of CNC Pipe Bending Machine

Some Benefits of CNC Pipe Bending Machine are as follows:

- Highly Precise: Provides highly accurate and consistent bending improvements ensuring superior quality in every pipe.

- Maximized Efficiency: Even automates the bending process ultimately boosting production speed, and cutting back on pragmatics.

- Versatility: Can bend a variety of pipe sizes and types under any conditions.

- Less Material Wastage: Minimizes errors with scrap material, optimizes costs with less expensive materials and keeps material use to the maximum.

- Works Complex Bends: Manipulates complex and closed radius solutions difficult to achieve manually.

Applications of CNC Pipe Bending Machine

Some of the applications of CNC Pipe Bending Machines are as follows:

- Automotive Industry: Utilized for the bending process of exhaust pipes, roll cages, and chassis components with high accuracy.

- Construction: Pipe bending for plumbing, HVAC systems, and structural components.

- Aerospace: Bends high-strength, lightweight tubes for fuel and hydraulic systems on aircraft.

- Oil and Gas: Complex pipework for pipelines, drilling equipment, and refineries.

- Furniture Manufacturing: Tube bending for frames, supports, and other components of furniture.

Shree Tube Tech Engineering, one of the preeminent CNC Pipe Bending Machine manufacturers in Chakan, offers high-precision and reliable solutions across industries. With our advanced technology and expert engineering, we develop tailor-made pipe bending machines to ensure accuracy, reduce material waste, and boost production efficiency all fit for long-term business success.